If we follow the instructions, there will be no air bubbles in all of our three types of powders; the 3mm wall thickness of the denture base tested in our lab did not show any problems.

- E-Shop

-

Labside

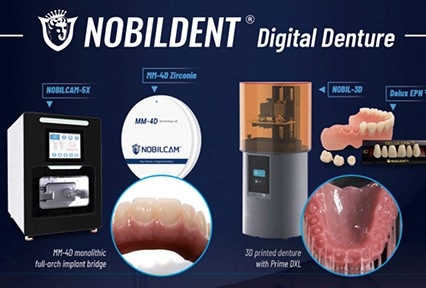

- NOBILDENT Delux EPN Artificial Denture Teeth

- NOBILDENT Prime DXL Artificial Denture Teeth

- NOBILDENT Select XL Artificial Denture Teeth

- NOBILCAM MM-4D MaxMultilayer Zirconia Discs

- NOBILCAM GM-3D Gradient Multilayer Zirconia Discs

- NOBILCAM MHT-Multilayer High Translucent Zirconia Discs

- NOBILCAM HS-High Strength Zirconia Discs

- NOBILCAM HT-High Translucent Zirconia Discs

- NOBILCAM AT-Anterior Translucent Zirconia Discs

- NOBILCAM Multilayer PMMA Discs

- NOBILCAM Flexible Discs

- NOBILCAM Monolayer PMMA Discs

- NOBILCAM Clear PMMA Discs

- NOBILCAM Pink PMMA Discs

-

Chairside

- PERFIT Putty

- PERFIT Heavy Body

- PERFIT Regular Body

- PERFIT Light Body

- PERFIT A-Silicone for Bite Registration

- Home Impression Kit

- HugeBond Universal Light Cure Dental Adhesive

- TopCEM Dual Cure Resin Cement

- TrusFIL-Flow Flowable Composite Restorative

- TrusFIL Universal Composite Restorative

- P-Etchant Phosphoric Acid Etching Gel

- HugeBond Universal FliPro Light Cure Dental Adhesive

- Proseal F Enamel Coating Resin

- UltraCore Core Build-up Material

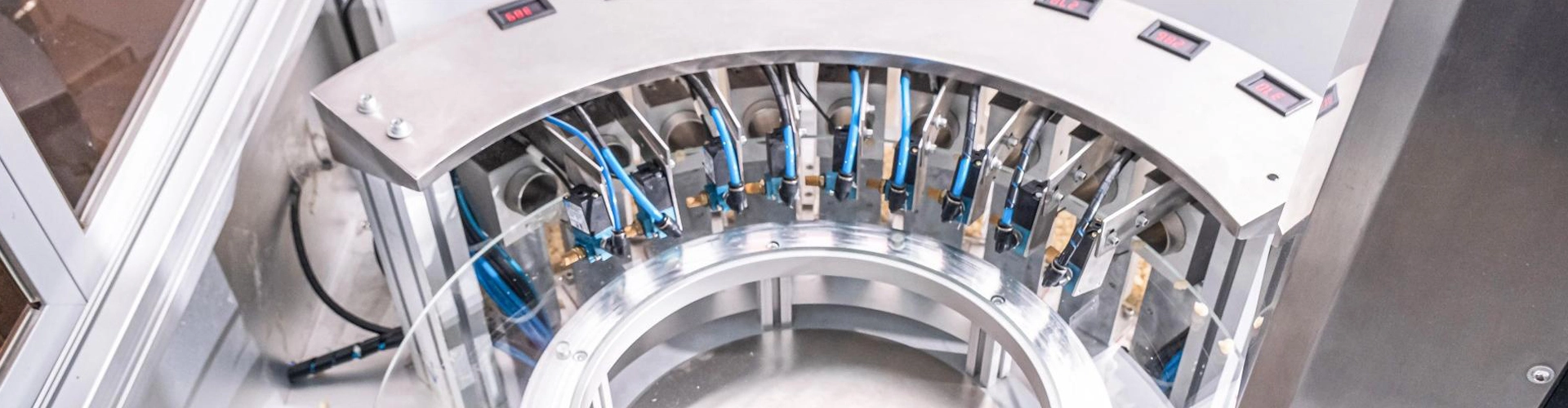

- Dental Equipment

- Solution

- Company

-

Contact Us

en

en