- E-Shop

-

Labside

- NOBILDENT Delux EPN Artificial Denture Teeth

- NOBILDENT Prime DXL Artificial Denture Teeth

- NOBILDENT Select XL Artificial Denture Teeth

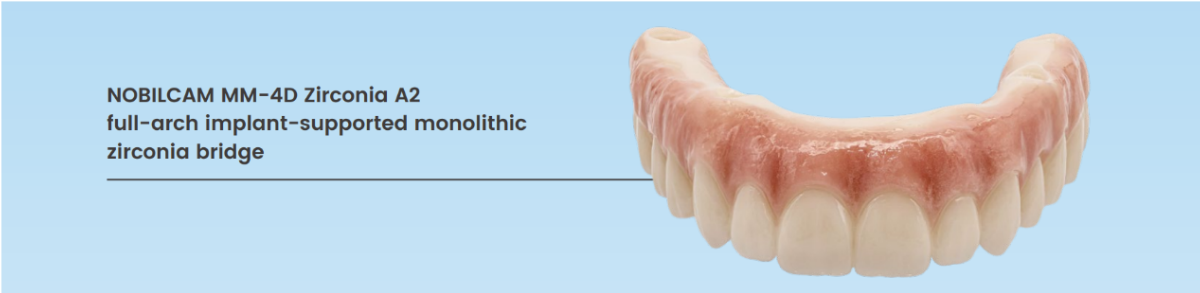

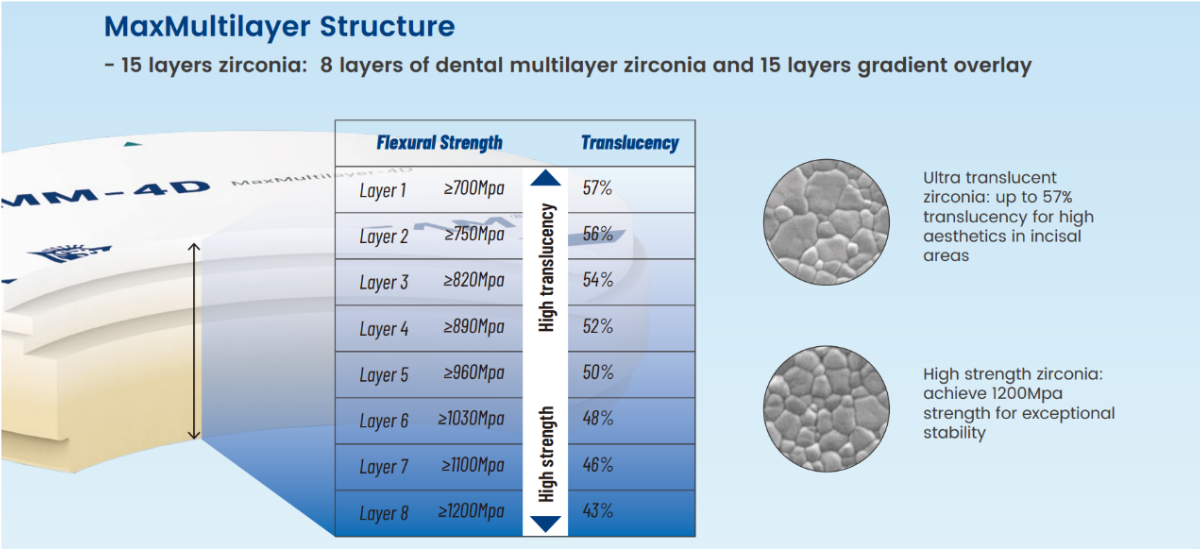

- NOBILCAM MM-4D MaxMultilayer Zirconia Discs

- NOBILCAM GM-3D Gradient Multilayer Zirconia Discs

- NOBILCAM MHT-Multilayer High Translucent Zirconia Discs

- NOBILCAM HS-High Strength Zirconia Discs

- NOBILCAM HT-High Translucent Zirconia Discs

- NOBILCAM AT-Anterior Translucent Zirconia Discs

- NOBILCAM Multilayer PMMA Discs

- NOBILCAM Flexible Discs

- NOBILCAM Monolayer PMMA Discs

- NOBILCAM Clear PMMA Discs

- NOBILCAM Pink PMMA Discs

-

Chairside

- PERFIT Putty

- PERFIT Heavy Body

- PERFIT Regular Body

- PERFIT Light Body

- PERFIT A-Silicone for Bite Registration

- PERFIT Tray Adhesive

- Dental Impression Kit

- HugeBond Universal FliPro Light Cure Dental Adhesive

- HugeBond Universal Light Cure Dental Adhesive

- P-Etchant Phosphoric Acid Etching Gel

- HF-Etchant Hydrofluoric Acid Etching Gel

- TopCEM-Ceramic Primer Ceramic Coupling Agent

- TopCEM Dual Cure Resin Cement

- TopCEM Elite System

- TopCEM-Veneer Light Cure Veneer Cement

- TopCEM-Try In Veneer Try-in Gel

- TopCEM Veneer System

- TopCEM Resin Modified Glass Ionomer Cement-Luting

- TopCEM Vigor SA Self-Adhesive Resin Cement

- TrusFIL Universal Composite Restorative

- TrusFIL-Flow Flowable Composite Restorative

- TrusFIL X-Blend Universal Composite Restorative

- TrusFIL Restoration System

- UltraCore Core Build-up Material

- Proseal F Enamel Coating Resin

- Pro Shield Fluor Protector

- Dental Equipment

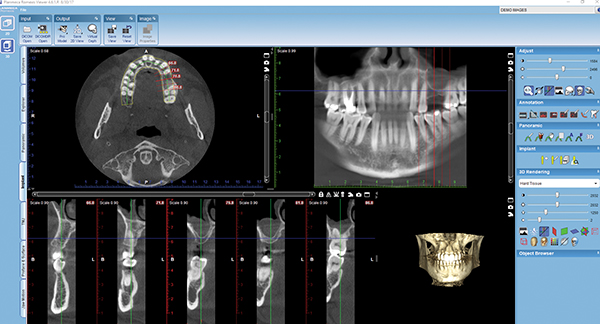

- Solution

- Company

-

Contact Us

en

en  ja

ja  fr

fr  de

de  es

es  ru

ru  ar

ar  th

th  vi

vi  id

id  hi

hi